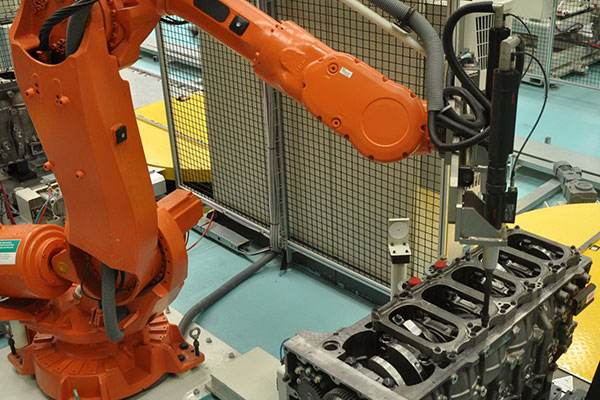

Engine Assembly Robotic Application

Comparing to traditional engine line, robotic assembly is faster and more precise, it could eliminate uncertainty brought by human workto improve production stability. So robotic engine assembly is a good choice for smart companies.

Detailed introduction

Product features

|

Engine is one of the core parts for automobile, thus the quality of engine influences directly the car quality. Because of many reasons, many engine lines are still by labor, which can not ensure quantity and quality. Also, manual line need high-skill operators, in this way mnay factories are lacking of young workers.

Advantages of robotic assembly,

1. Easy positioning. There is no need for highly precise tray or positioning structure.

2. Robot is standard equipment, lead time is not long.

3. Only need to change jig tooling and its accesories when need to change into other usage.

4. Robot works fast. It saves cycle time and improves assemble capacity.

5. High precision. It ensures product consistency and increase product quality.

6. Robot could work for 24 hours per day. It increases work efficiency.

7. Good rigidility. It saves maintainence cost.

|

|

|

|

By combination of robot and jigs, complicated and smart operation can be achieved. Engine turnover, bolt tightening, gluing and more workstation could use robot. And one robot could finish various process, for example, you could integrate tightening, turnover and torque measuring on one robotic application. Moreover you could intergrate various robots with different function as a line to achieve more complicated operation.